Specifications

The process of defining the functional and qualitative standards, requirements and specifications of materials, components, products and services.An engineer draws up a diagram of the dimensions and material properties of a widget.

A business unit develops a use case for how a customer logs in to a mobile app.

A bank develops customer service policies, practices, principles and procedures for telephone banking inquiries.

An electronics manufacturer documents specifications of the sound quality of a speaker product.

Planning

The process of planning to achieve the quality of products and services as documented in specifications and standards. This includes planning test cases and measurements.A quality control team uses requirements to develop a quality management plan that includes measurable quality objectives.

A restaurant develops a procedure for validating the quality and food safety of delivered ingredients.

A kitchen manager develops a checklist that is used to prepare menu items.

A chef develops a guideline for the presentation of an entree.

A restaurant develops a process whereby the kitchen manager monitors the quality of dishes as they are completed.

A construction site manager develops a procedure for confirming that concrete being poured at a site is the correct consistency and mixture.

A quality control team develops test cases that will be used to test each unit of a product off an assembly line.

A house builder develops an quality checklist for confirming the quality of each phase of house construction.

A customer service team develops screens that guide representatives though the policies and actions that apply to each service scenario.

Production

Implementing production controls that achieve quality objectives.A scanner at a production line workstation confirms that widgets are the correct weight and dimensions before they are installed in a machine.

A prep cook follows a checklist when they prepare a salad.

A kitchen manager monitors the quality of all outgoing food items and regularly sends low quality items back to be corrected or redone.

Workers on a bicycle production line are empowered to stop the line to address a quality problem such as units that are deformed by a malfunctioning machine.

Inspection

Quality inspection is the process of confirming that quality conforms to requirements and standards. This can be applied to materials, components, products in the middle of manufacturing and finished products.An automated test is run on air conditioning units to confirm that each unit responds to a set of commands as expected.

A new house under construction is inspected by local building inspectors to identify violations of building codes.

Quality control staff visually inspect loaves of bread before and after they are packaged on a production line.

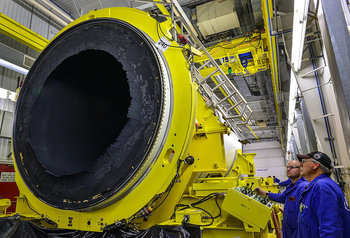

An aircraft engine is inspected by mechanics and put through a series of performance tests before being delivered to the customer.

An aircraft manufacturer tests engines it receives from a subcontractor.

A farmer grades fruit as part of the packaging process whereby fruit that is defect free and the ideal size receives the highest grade and is sold as fruit. Other grades may be used to make juice or prepared fruit products.

Service Delivery

The process of controlling service quality as a service is being delivered.Hotel staff follow strict guidelines that define how to address customers and how to handle a wide range of common service scenarios.

Service staff in a restaurant are trained to identify quality problems before serving food to a customer.

Monitoring

The process of monitoring service quality to correct quality problems as they occur.The front desk manager at a hotel monitors for customers that require special assistance and service interactions that aren't going well and steps in to correct things.

A bank monitors customer service interactions over electronic and telephone channels to identify performance problems and process shortfalls.

An ecommerce retailer gives customers an opportunity to rank each customer service interaction and send comments that are reviewed by quality assurance teams.

Improvement

The process of improving the quality control process itself. The process of improving the quality of products, such as design changes, is viewed as a quality assurance process.A farmer purchases an automated sorter to reduce the cost and effort of grading fruit. This also increases accuracy.

An automated testing script fails to identify defects in a production run of air conditioners. This results in a number of returns and damaged brand reputation. The script is updated and tested to catch these defects on subsequent production runs.

| Overview: Quality Control Process | ||

Type | ||

Definition | The process of ensuring that quality conforms to standards and requirements. | |

Related Concepts | ||