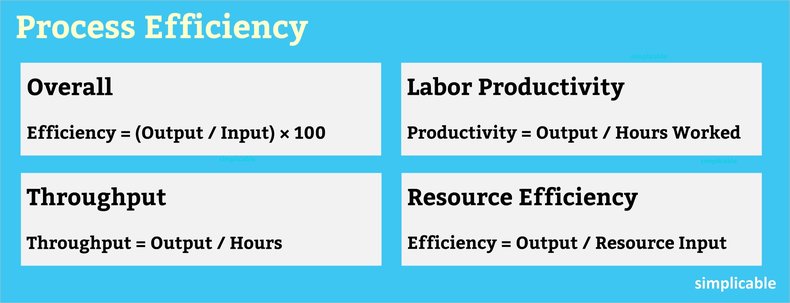

Overall Efficiency

The overall efficiency of a process is the value of outputs divided by the value of inputs. For example, a production line that takes inputs of $1 million a day and produces outputs value of $1.2 million:efficiency = (1.2 / 1) × 100 = 120%

An overall efficiency of over 100% indicates a process that adds value. Process Throughput

Throughput is the output of a process or machine for a unit of time.throughput = output / hours

For example, a production line that outputs 30,000 units in 12 hours.throughput = 30,000 / 12 = 2500 units / hour

This can be used to measure bottlenecks. As a simple example, if you have 12 steps in a sequential process, the one with the lowest throughput is a bottleneck.

Labor Productivity

Labor productivity is output for an hour worked.productivity = output / hours worked

For example if you produce 1.2 million dollars in value on a 12 hour shift with 12 workers:productivity = $1,200,000 / (12 x 12) = $8333/hour

Resource Efficiency

Efficiency can also be measured for any resources consumed by a process such as materials, energy and water.resource efficiency = output / resource input

For example, if it requires 90 kWh of electricity to produce 30,000 units:energy efficiency = 30,000 / 90 = 333.3 units / kWh

Efficiency can be measured for any process input in order to optimize costs or reduce environmental impact. Summary

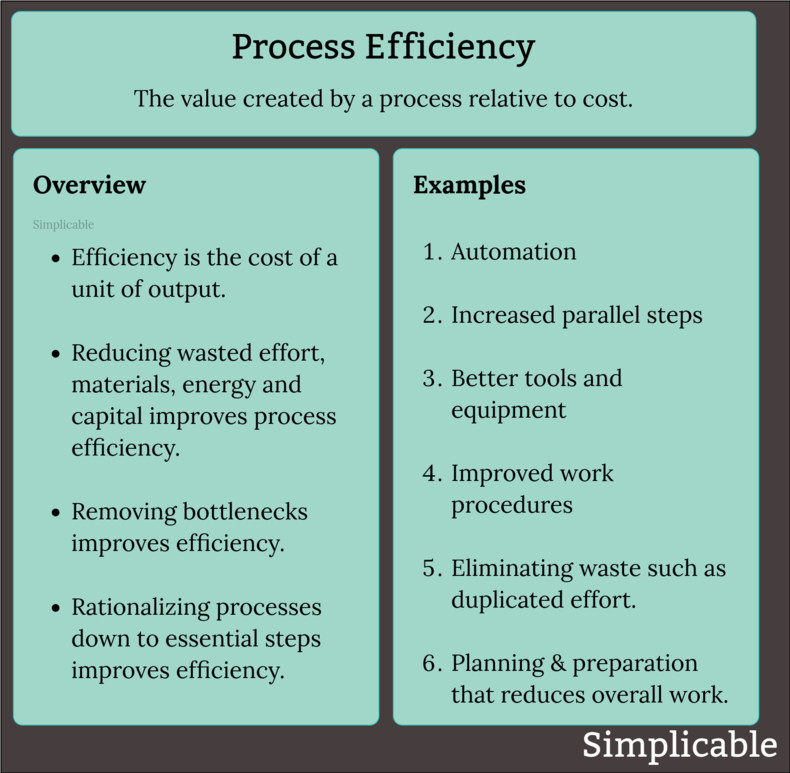

Process efficiency is the cost of the value produced by a process. Improving process efficiency can involve automation, investment in tools, training and optimization of process steps.

| Overview: Process Efficiency | ||

Type | ||

Definition | The output of a business process for a unit of input. | |

Related Concepts | ||